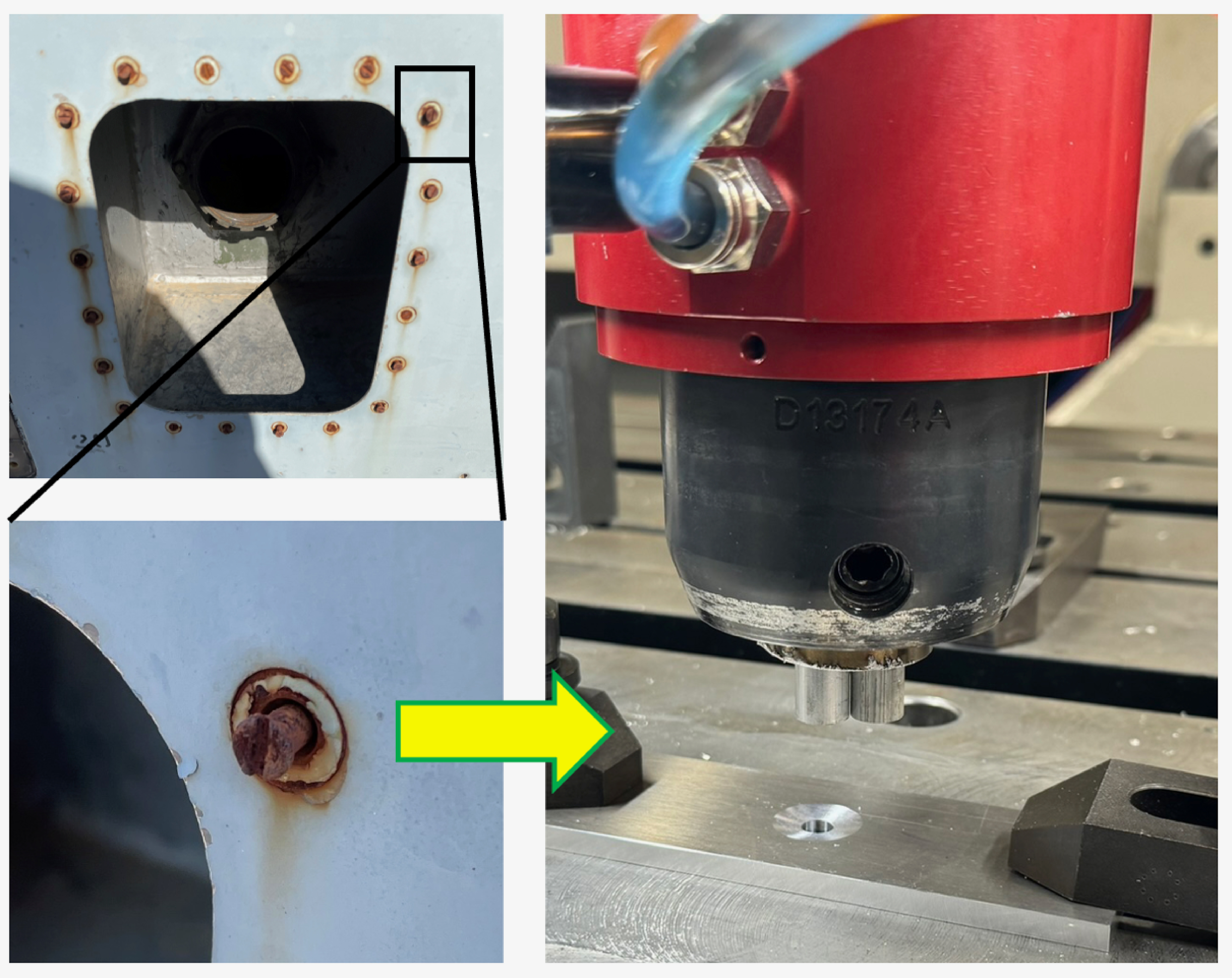

Figure 1: Example of corroded fastener site and sample new printed material.

The Department of Defense (DoD) relies on thousands of aircraft and vehicles for a variety of operationally focused missions, including testing, training, and combat operations. When these platforms are grounded for repairs or awaiting replacement parts, it directly impacts mission capabilities.

Whether it's a corroded fastener deep in the wing of an F-18 or an invisible crack in a composite drone, damage adds up—in cost, time, and reduced operational capacity. Even a minor bracket can cost thousands of dollars and take six months or more to replace.

To address this challenge, the Strategic Environmental Research and Development Program (SERDP) and the Environmental Security Technology Certification Program (ESTCP) have invested in innovative repair technologies that promise to dramatically reduce maintenance burdens while increasing platform resilience.

This funding includes two groundbreaking approaches that have promise to transform how the DoD maintains its fleet, potentially saving millions in costs while keeping more assets mission ready.

Printing New Life into Metal Components

For Navy aircraft operating in corrosive saltwater environments, fastener sites are particularly vulnerable to damage. The aluminum alloys used in these critical components present a unique challenge: they can't be welded using conventional methods, and replacement parts often face lengthy lead times.

Researchers Dr. Paul Allison and Dr. Brian Jordon from Baylor University have developed a novel solution: Additive Friction Stir Deposition (AFSD). This solid-state 3D printing process allows repair teams to essentially "print" new material directly into corroded or damaged areas without melting or weakening the surrounding structure.

"There's a sweet spot where the temperature is in the Goldilocks zone – apply enough heat but not too much," said Dr. Jordon. This precise control allows the team to maintain the nanoscale properties that keep the repaired material strong and flight-worthy.

The technology specifically targets areas with corroded fastener holes in fuselage parts and wings. When these holes become enlarged due to corrosion, maintenance crews typically have limited options – either use bushings, which can only be done a few times per area, or replace the entire part. By extending aircraft life through targeted repairs rather than wholesale part replacement, the approach promises substantial cost savings and reduced downtime.

Self-Healing Composites: The Future of Maintenance

While Drs. Allison and Jordon address metal components, Dr. Jason Patrick’s team from North Carolina State University is tackling another critical material: fiber-reinforced polymer (FRP) composites used extensively in aircraft and other military platforms.

These lightweight materials are prone to micro-cracks and delamination that typically occur beneath the surface, making them difficult to detect without time-consuming inspections. Left unaddressed, these hidden flaws can grow into catastrophic failures.

"There's not a lot of room for error in composites, especially for the DoD," Dr. Patrick said.

His team's breakthrough is a self-healing FRP composite that is more resistant to damage and can self-repair after damage without human intervention. The system combines carbon or glass fiber reinforcement with a specialized thermoplastic adhesive (EMAA) that can re-mend itself when melted via built-in heating elements.

Unlike earlier self-healing materials that could only repair once or required complex fluid delivery systems, Dr. Patrick's innovation can heal repeatedly—more than a thousand times—and can restore nearly the original material quality each time.

"We weren't the first to look at self-healing via thermal re-mending, but we were the first to demonstrate it repeatedly and in situ, that is without the need to remove from the service environment. Others had to place composites in an oven for instance to repair, which sort of defeats the practicality of self-healing,” Dr. Patrick said. "We are excited to continue advancing this platform for the DoD and industry applications.”

Technology Maturity and Next Steps

Both projects are making significant progress toward field deployment. Dr. Patrick’s patented self-healing composite technology is currently at Technology Readiness Level (TRL) 3 – proven in the lab, with upcoming plans to commercialize. It has been licensed to a startup company he co-founded in 2023: STRUCTERYX, INC.

With strong expressed interest from multiple branches of the DoD (Army, Navy, Air Force), the team is working towards a minimum viable product (MVP) that meets essential military needs with eventual field deployment as the goal. They're also exploring pairing their self-healing composites with onboard sensing technology to detect damage and sense repair.

Meanwhile, the Additive Friction Stir Deposition team is talking with SERDP and ESTCP about a future demonstration at a DoD installation. There's growing interest in robotizing the process – scaling it down for use on mobile repair systems that could operate directly on aircraft.

Investing in DoD Connections

Perhaps equally important to the technological breakthroughs is the investment these projects represent in developing the next generation of defense researchers and engineers.

"We get to collaborate on research that impacts the armed forces… students can see the direct correlation and are motivated and excited by that," said Dr. Allison. “These students aren't just learning technical skills, they're gaining direct experience solving real-world defense challenges.”

"They're the workforce we're producing. They're transitioning this knowledge not just in a lab setting, but to the warfighter," said Dr. Jordon.

SERDP and ESTCP Leadership in Advanced Materials

The work on advanced repair technologies represents just one facet of SERDP and ESTCP's broader investment in materials science innovation for defense applications. By bringing together academic researchers, industry partners, and military stakeholders, these funded projects create a powerful ecosystem for developing and deploying solutions to real operational challenges.

To learn more about SERDP and ESTCP’s commitment to long-term chemical and material resilience and extending the service life of mission-critical weapons systems, visit the Chemicals and Materials focus area web page to see related projects and open funding opportunities.

###

About SERDP & ESTCP

The Strategic Environmental Research and Development Program (SERDP) and the Environmental Security Technology Certification Program (ESTCP) develop and demonstrate innovative, scalable technologies that enhance military readiness, improve warfighter capabilities, and strengthen defense infrastructure. SERDP invests in basic and applied research to secure military installations, and ESTCP puts innovations to the test, fielding real-world solutions that enhance military operations. The programs report to the Deputy Assistant Secretary of Defense for Energy Resilience & Optimization headquartered at the Pentagon. For more information, visit https://serdp-estcp.mil.